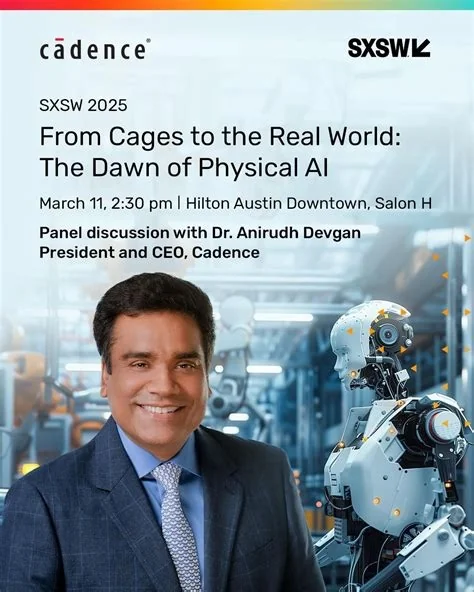

Physical‑AI robots that blend advanced artificial intelligence with real‑world actuation are now in commercial production at a price of $20,000‑$30,000 per unit. This cost structure enables businesses in high‑wage economies to achieve rapid return on investment through continuous operation, reduced errors, and data‑driven process optimization.

Key Market Drivers Reducing Costs

AI‑Focused Data Centers Lower Compute Expenses

Massive investments in AI‑centric data centers are driving down the price of high‑performance compute, making edge‑ready processors more affordable for robot manufacturers.

Edge‑Compute Semiconductors Enable On‑Device Intelligence

New generations of edge‑optimized chips deliver the processing power needed for real‑time perception and decision‑making directly on the robot, eliminating reliance on costly cloud services.

Maturing Sensor and Actuator Ecosystem

Advances in low‑cost sensors, precision actuators, and large‑language models create a robust hardware‑software stack that supports autonomous “sense‑think‑act” cycles.

From Prototype to Production

Manufacturers have moved beyond laboratory demos to ship ready‑to‑use units. Production lines are now calibrated to deliver robots at the $20‑30K price point, targeting small‑ and medium‑size enterprises that seek automation without prohibitive capital outlay.

Real‑World Applications Emerging Now

Physical‑AI systems are being deployed across multiple sectors, delivering tangible productivity gains.

- Manufacturing: Intelligent tightening and torque‑control robots provide consistent results, real‑time feedback, and automatic fault alerts.

- Logistics: Warehouse pick‑and‑place robots handle high‑speed sorting and inventory movement with minimal human supervision.

- Healthcare: AI‑enabled diagnostic equipment performs precise measurements and assists clinicians in real time.

- Infrastructure Inspection: Autonomous drones navigate complex terrain to capture high‑resolution data for predictive maintenance.

Training Paradigms Accelerating Capability

Modern robots leverage a suite of learning techniques that shorten development cycles and expand functional breadth.

- One‑shot learning – mastering a task from a single demonstration.

- Zero‑shot execution – inferring actions without explicit training.

- Reinforcement learning – improving performance through trial and error.

- Imitation learning – copying expert behavior to accelerate skill acquisition.

- Integration of large language models – translating high‑level commands into executable motions.

Economic Impact and ROI Calculations

In high‑wage regions, skilled labor costs often exceed $70,000 annually. A physical‑AI robot operating continuously can recoup its $20‑30K purchase price within 12‑18 months by reducing labor expenses, minimizing errors, and increasing throughput. Additional benefits include lower waste, higher product quality, and valuable operational data for continuous improvement.

Future Outlook for Physical AI Robots

The convergence of affordable compute, advanced sensors, and sophisticated training methods positions physical‑AI robots for widespread adoption. Over the next five years, billions of dollars in capital expenditure are expected as manufacturers, logistics firms, and healthcare providers integrate these systems into daily workflows, reshaping supply chains and competitive dynamics across high‑wage economies.